Outdoor shades roller blinds awnings sun screen zipper blinds welding machine

Model No.︰RD-HJJ300

Brand Name︰Ridong

Country of Origin︰China

Unit Price︰US $ 3000 / pc

Minimum Order︰1 pc

Product Description

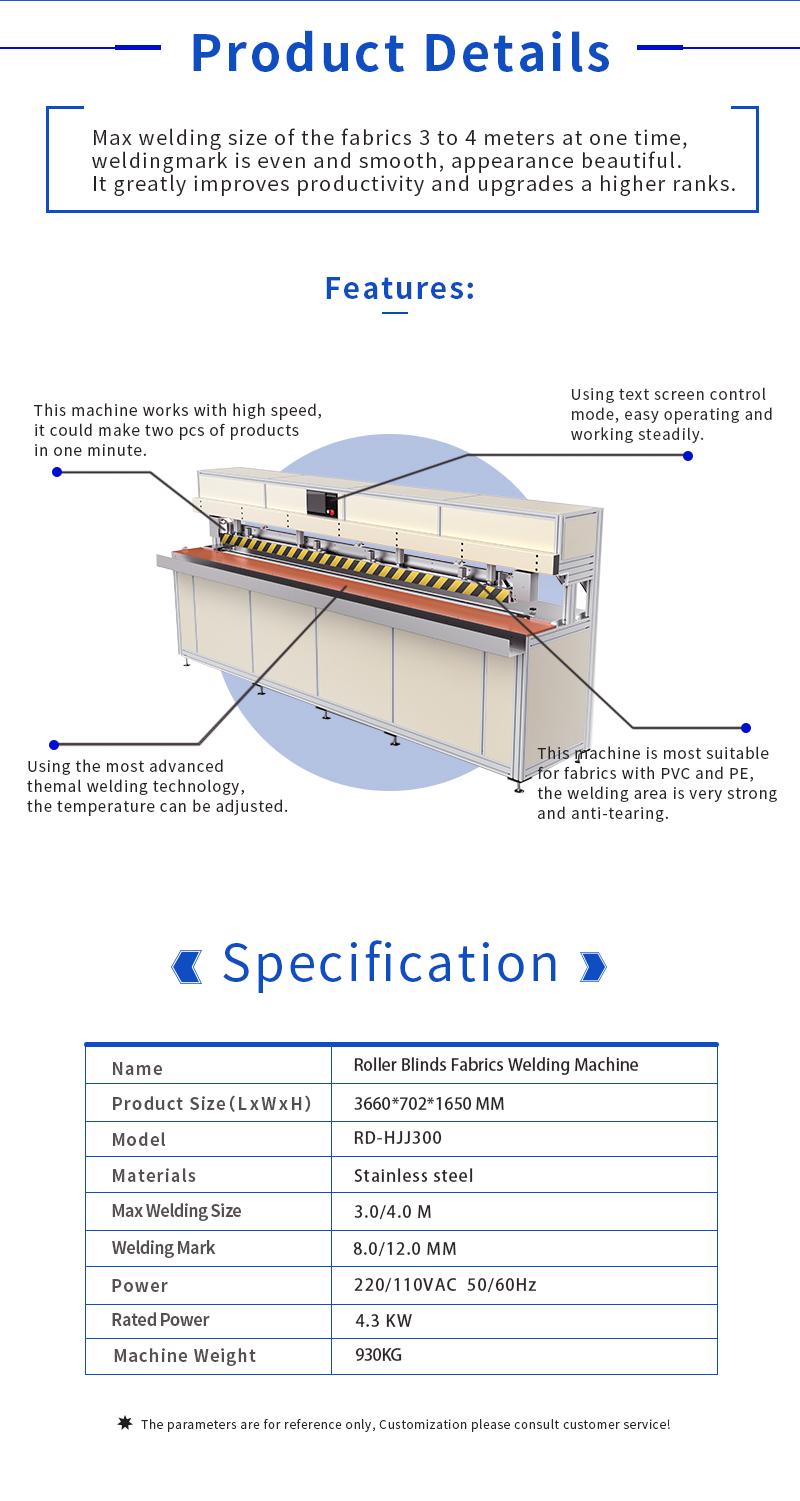

Blinds Shades Rubber Plastic Strips Zippers Multifunction Welding Machine

FUNCTION:

a> This machine is available to welding any fabric, such as roller blinds,awning blinds,shutters, shades...or other fabric which with PVC materials.if the fabrics is with PVC as ingredient , then the fabric can be welded directly, or it is must set PVC strips to infill the gap to be welded and the perfornace is perfect as well.

b>The welding time could adjustable according to different materials.

c>The machine can replace traditional sewing machine,because it improve the quality and grades of products.

d>The machine have automatically technology of fold/butt /edge weld,the edge fold can be operated itself automatically,the edge trimming width also can be adjusted within 25~55mm,and the width between the fold and welding line can reach to 3000mm which solve the problem of welding for many times.

OUTSTANDING FEATURES:

1. fabric fold welding,butt welding, edge welding,roller blinds PVC tape/strip welding.

2. used for all kinds of fabrics, mainly for roller blinds.

3. weld length&time adjustable.

4. the max fabric welding width up to 2.5m3.0m/4.0m ..or design by your needs.

5. welded curtain with good welding quality, high efficiency, succinct,easy operated, no fluffy,no burning,no color fading off.

6. the whole welding time could be finished in 20 sec, and adjustable by your materials.

7. The machine replace traditional sewing machine,because it improve the quality and grades of fabrics.

8. Welding length can reach to 3m which with high efficient(the traditional machine only can reach about 1m)

9. Can fold by itself (the traditional needs to operate it by hands).

10. The voltage of the heating part is only 36V with infrared control, so using security (the traditional is not security).

Fabric welding effect:

Mini Welding Machine:

We attend:

Package: standard export disinfected wooden case.

Machines have been exported to:

Iraq, Dubai, Kuwait, Kazakhstan, Poland, England, Australia, New Zealand, Belgium, Belarus, Russia, Spain, Canada, America, Mexico, Columbia, Chile, Brazil, Argentina, South Africa, Indonesia, Turkey, Bulgaria, Malaysia, Singapore, Taiwan, Hong Kong etc.

Common Questions:

1> How long is the welding maximum width?

Answer: 2.0m/3.0m or according customers requiryment.

2> what does the welding time on the control screen mean ?

Answer: There are two patrs:one is the fabric welding time is 16 seconds. the other is cooling time is about 8 seconds.

3> Why is it eaiser to tear apart after welded ?

Answer: The heating time is not enough

4> How to adjust the fold width range ?

Answer: Adjust the hand wheel which on the left of the machine and adjust the press bar.

5> What kind of materials suitable for hot air welding ?

Answer: All the fanrics on the market.

6> What's the rated power and power?

Answer: 8.0 kw, 220 V

AFTER-SALES SERVICE:

1. Free warranty period for first year. We are supply the parts and maintain on free except non-normal damage

2. The supplier offers the part of a part of the equipment and relevant spare part to charge costs separately after free guarantee period.

3. All the products sold out enjoy one year warranty and full life mechanical maintenance.

4. Over of the Free warranty period, the user must pay the cost of replacement parts.

5.after the warranty period, provides the technical support and the compensated service.

Payment Terms︰ TT / LC / DP / DA

Product Image